Slide bearing inspections

Bearings are responsible for more than 50% of all failures in electrical machines. Therefore, it is important to perform regular inspections. SPIT helps you do this.

Troubleshooting

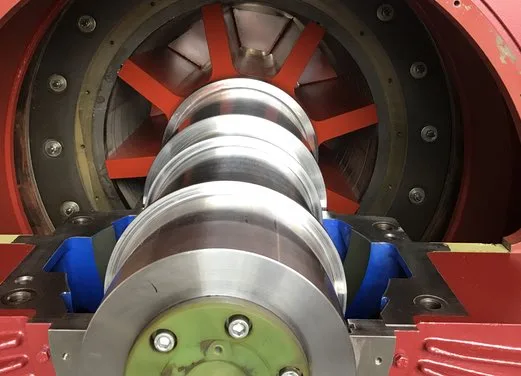

Types of plain bearings and repair

The most common causes of failure are (normal) wear and tear, lubrication problems, contamination or electrical damage affecting bearing surfaces. While rolling bearings are the most common type of bearing, plain bearings are most often found in larger machines that require a bearing life that rolling bearings simply cannot achieve. Especially if they are properly cared for.

Inspections

SPIT can non-destructively inspect your plain bearings using ultrasonic, magnetic and penetrant testing. Our engineers are trained to ISO 9712 and/or ASNT Level 2 as a minimum.

Ultrasonic examination

High-frequency sound is used to examine a material. Ultrasonic testing (UT) is used for thickness measurements and finding defects in the adhesion of the white metal to the bearing shell.

Magnetic research

Magnetic testing is used to detect surface abnormalities in ferromagnetic metals. Imperfections are made visible by applying magnetic particles.

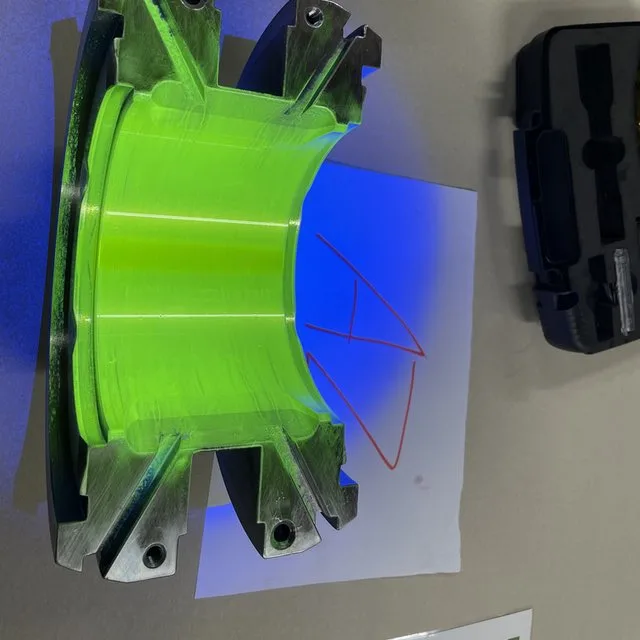

Penetrant research

Penetrant examination is used to find defects that are in open connection with the surface. Thus, these defects become clearly visible.

Why plain bearings?

Slide bearings have several names, including Babbitt bearings, slide bushings, tapered roller bearings and plain bearings. They are crucial to the proper operation of rotating machinery of which they are a part.

They can serve multiple purposes simultaneously: limit motion, act as guides, provide support and reduce friction. They work with linear, rotary and oscillatory motion. Slide bearings are cylindrical in shape and are straight, so they are not tapered or conical.

The clearance between bearing and shaft has a major impact on the life and performance of plain bearings, and there are numerous guidelines and rules of thumb you can find to tell you how much clearance you need.

However, there are certain things that will always affect proper clearance:

- Whether the axis is arranged vertically or horizontally

- Oil viscosity and load

- How much weight the bearing must bear

- Ratio of length to diameter

- Peripheral speed of the axle journal

Contact

Want to know more?

We would love to hear what your industrial balancing needs are. With our experience and our extensive workshop, we can help you in the way that suits your business.